Request a Demo

Trusted by leading brands, retailers, manufacturers and service providers across industries such as:

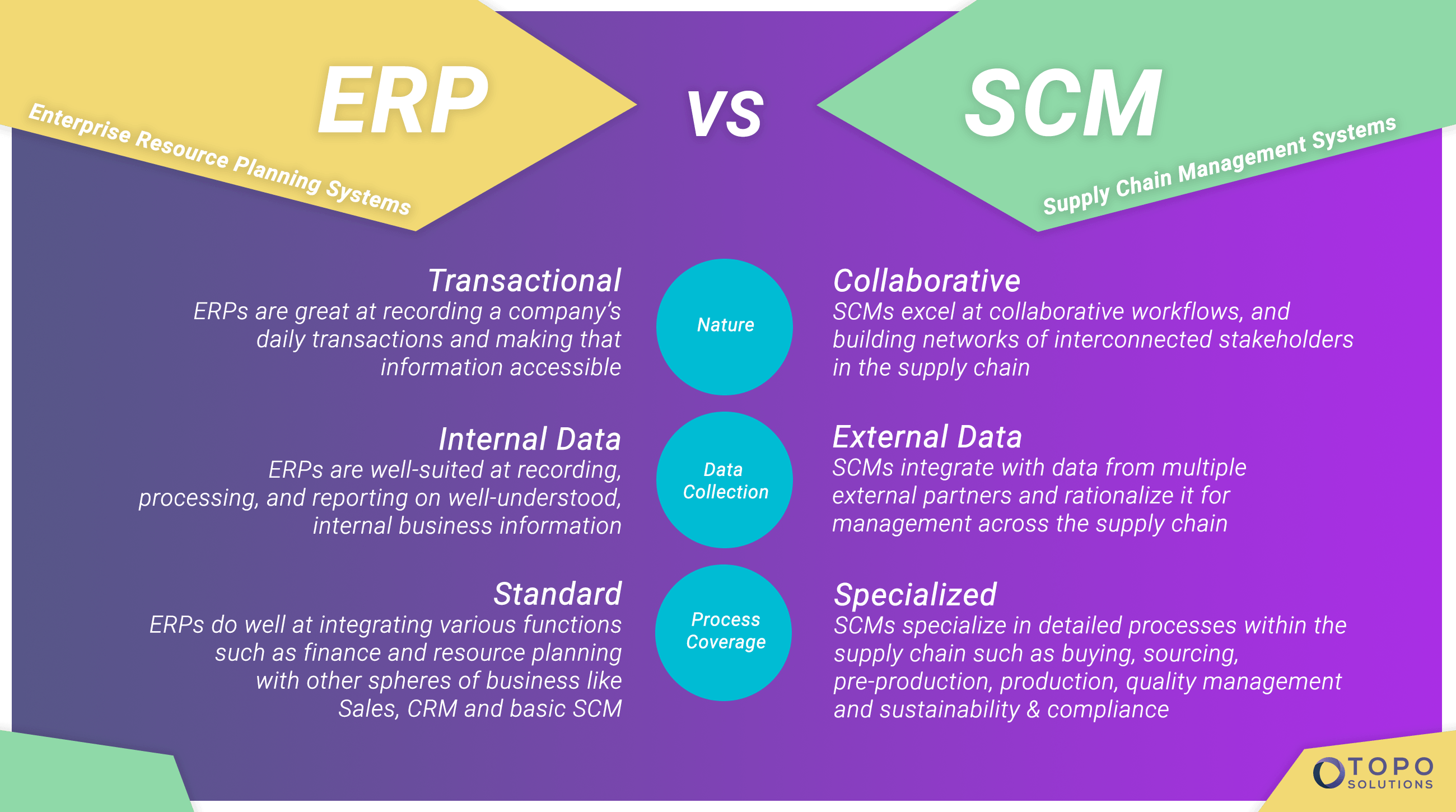

Ultimately, the choice comes down to optimizing your workflow management as you digitize your business. A “one-size-fits-all” tool isn’t ideally suited to managing both internal, transactional data (like an ERP) and external, collaborative relationships (like SCM).

“Potential problems occur when one type of software attempts to fulfill every business need. Yes, many software suites feature modular components that allow the system to be configured with different functionality based on the needs of the user. However, particularly in areas such as supply chain management, there can be a great deal of complexity. That in turn can lead to a system that is complex to the point of no longer being intuitive and user friendly, decreasing user adoption and leading to workarounds and using less-than-efficient systems.”—Technology Evaluation Center, ERP vs. SCM – Which Software Is Best for Your Business?

We’ll explore:

A specialist SCM tool will help you maximize transparency and product quality, reduce operational costs, eliminate delays, and build trusted relationships with your suppliers.

For medium and large businesses, ERP software provides a transactional, data-driven foundation to understand what’s happening across the organization.

“As the name suggests, ERP’s primary goal is to manage the various resources within the company to make sure they are being utilized in a cost-effective way. It is also designed to make sure that all resources are being used efficiently.”—Corporate Finance Institute, What is Enterprise Resource Planning (ERP)?

Depending on the platform’s capabilities, ERP systems and their integrated applications help businesses to:

ERP systems provide this functionality across multiple business areas. Outside of supply chain management, this may include:

Supply chain management areas supported by an ERP might include:

So, if an ERP provides supply chain management capabilities, why would you need a separate supply chain platform? We’re glad you asked.

SCM platforms are collaborative, relationship-based software that helps businesses to track, manage, and optimize the flow of products as they pass through the global supply chain.

“Supply chain management (SCM) software is designed to help companies meet customer demand in the most efficient, cost-effective manner possible by tracking the strategic movement of products and materials from their original source to the factory, warehouse, store, customer, and through return or disposal.”—TechnologyAdvice, What is supply chain management?

Depending on the platform’s capabilities, SCM systems help businesses to:

SCM systems deeply integrate throughout the supply chain to gather data, support supply chain stakeholders, and provide additional capabilities to all parties:

You need the right tool for the right purpose. ERP and SCM platforms have different design philosophies and ways of working:

Let’s break this down a little more.

Of course, this doesn’t mean that ERP systems cannot gather external data, or that SCM systems can’t be used for transaction analysis—-it’s mainly about identifying where the strengths of each platform lie. In an increasingly competitive marketplace with a strong focus on digitization, businesses increasingly need specialized tools that can adapt to unique circumstances.

Ultimately, ERP platforms tend to be built around older ways of thinking—what’s easy to measure and improve in very specific, predefined ways. Next-generation SCM platforms are designed to be flexible and adapt to the continuous changes inherent in global supply and demand.

Now that we’ve explored some of the key strengths and differences between ERP and SCM, it’s helpful to explore key business functions. There are overlaps between the functions of the two types of systems, but each definitely has strengths in specific areas.. Here’s how each of these tools will help you integrate and optimize supply chain management.

Ultimately, an ERP is a great choice for easily understood, predefined, data-driven business processes like accounting and reporting. An SCM, on the other hand, gives you powerful options for daily collaboration, communication with supply chain partners, tracking and meeting milestones, and doing complicated, detailed supply chain work.

The great thing is, you can have both. Modern SCM platforms integrate flawlessly with ERP systems to provide major benefits whatever type of data, process, network, or other supply chain aspect that you’re dealing with.

Still not convinced? Here are some thoughts when it comes to deciding on the best tools:

SCM platforms like Topo aren’t just for operational supply chain management—they can also help you discover new products, drive sustainability, plan contingencies, and lead a continual optimization program.

If you want optimal results, you need optimal tools. If you have a complicated supply chain, an SCM tool is going to give you much more of a competitive advantage than an ERP.

Topo is a powerful network that connects all stakeholders of your supply chain. We cover the entire journey of your products, from sourcing, product development, ordering, production to quality, chemical, and sustainability management. Our supply chain platform digitally transforms your business— regardless of your industry. Topo allows you to collaborate remotely, automate processes and analyze data within your supply chain in real-time to increase transparency and productivity while decreasing operational cost.

Topo is a whole new breed of software tackling problems that existing ERP, PLM, or Supply Chain Management systems simply cannot solve. Our integrated Low-Code App Builder allows you to build fully customized interfaces, automated workflows, and dashboards for your current and future use cases.