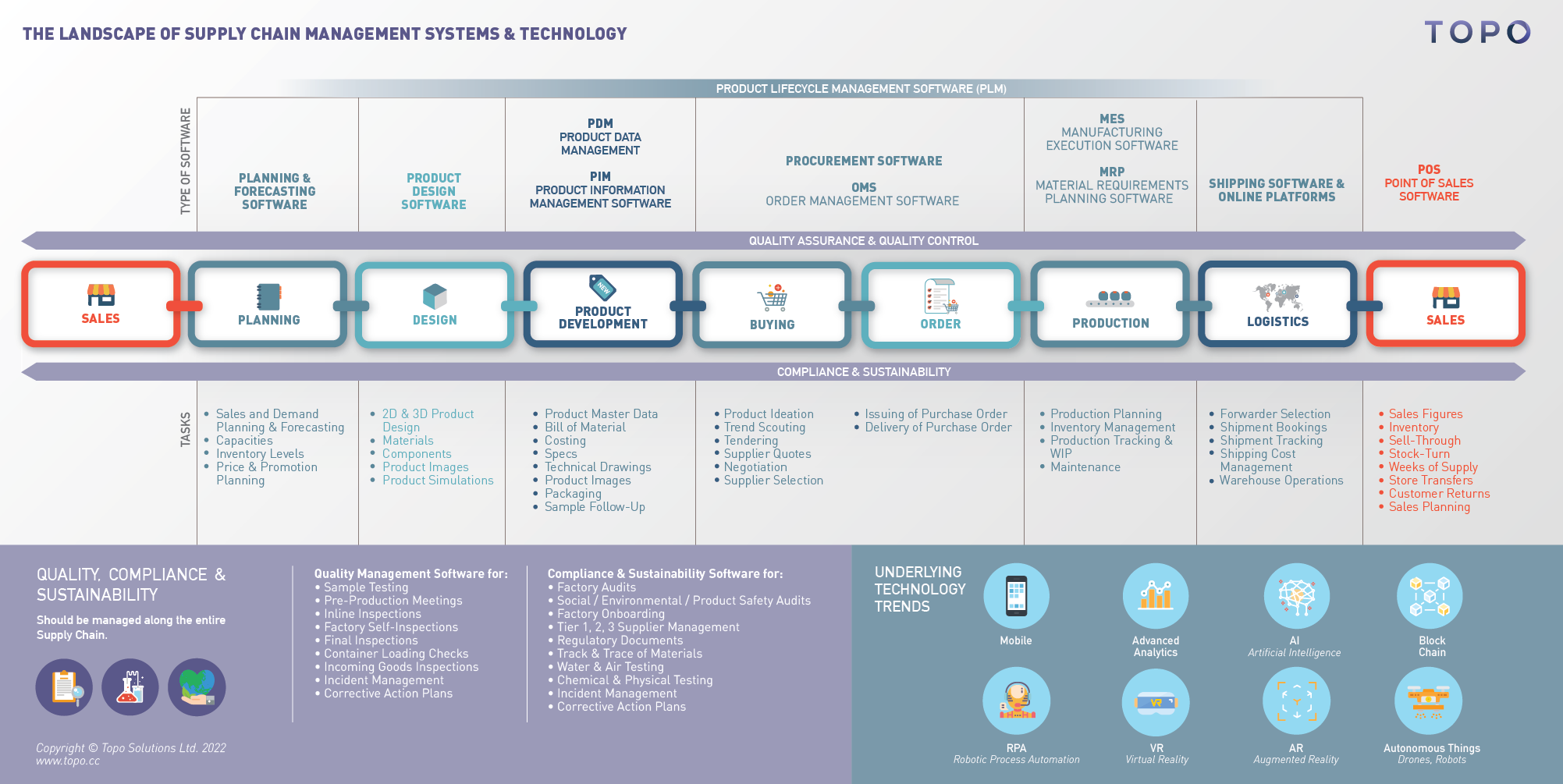

International supply chains are incredibly complex. Supply chain stakeholders must understand and manage vast amounts of information, ensuring the smooth flow of data, materials, and products at every stage. It’s a huge challenge.

A digital supply chain platform brings together all of your data and processes to provide a centralized, real-time view of your supply chain. It helps you to collect, track, process, and act on information from across all of your supply chain partners.

A digital supply chain platform empowers you to lower costs, stay compliant, reduce risks, speed up time-to-market, eliminate problems, and gain transparency. This cloud software will integrate with other applications, systems, and data stores from across your supply chain partners, providing a trustworthy, complete, and holistic view of your operations.

Used correctly, the right platform will transform your supply chain business.

There are several trends influencing the move to digital platforms–from competition and economics, through sustainability and politics, to technology and industry.

Increasingly, governments and other regulatory bodies are introducing new legislation and compliance rules for the sourcing, manufacture, and logistics of materials and products. These range from strong Environmental, Social, and Governance (ESG) standards through to ensuring a level playing field and economic opportunities for all.

One recent example is a new German supply chain law that “imposes significant obligations on companies that source their products and services through supply chains from developing and emerging countries and sell them in Germany to comply with human rights and environmental standards.”

We have similar encouraging initiatives in many areas and countries. For instance, the New York Fashion Sustainability and Social Accountability Act (“Fashion Act”), currently under consideration in the New York State Assembly, would require companies to map their supply chain and disclose environmental and social responsibility criteria in public reports. If passed, this legislation will mandate greater accountability over companies’ sustainability efforts. It will also require companies to undertake extensive due diligence and subject companies to a potential private right of action.

Digital supply chain platforms allow businesses to track ESG performance and regulations across multiple areas to ensure they stay compliant.

Consumers are becoming increasingly aware of the environmental impact of the supply chain. At the same time, governments are implementing stricter environmental controls.

It’s something we think about a lot at Topo, and we’ve previously stated that, “We’ll also see new legislation come into effect, from individual states in the U.S. to new laws in China and standards in other parts of the world. Whether it’s a carbon tax, cap, and trade, or other methods, the need to reduce greenhouse gasses is a major driver for new policies.”

The best digital supply chain platforms make it easier to track and reduce emissions and other environmental risks. This positions businesses to easily adapt to new legislation and reassures consumers that they are implementing robust sustainability approaches.

Inflationary trends, trade wars, and COVID-19 are significantly increasing supply chain costs, while globalization means that competition is becoming increasingly fierce. Supply chain firms have seen profit margins slashed, forcing ever-keener pricing that hurts the bottom line.

There’s a huge need to understand every cost involved in sourcing, manufacturing, storing, transporting, and selling products–from individual unit economics to fixed costs, fuel, tariffs, and other expenses. A digital supply chain platform can help, significantly increasing transparency, with end-to-end visibility that allows for better cost control, pricing, and profit margins.

We’ve seen an enormous acceleration in technological change over the last decade–cloud technology, Big Data, smart logistics, AI, IoT devices, and other innovations change the way supply chains function, communicate, and deliver. In fact, we believe that we are about to enter a new phase in the Industrial Revolution that focuses heavily on interconnectivity, automation, machine learning, and real-time data.

Industry 4.0 is where our sourcing, manufacturing, and industrial processes meet the digital age. This impacts the supply chain industry as part of “Supply Chain 4.0” which McKinsey describes as, “The application of the Internet of Things, the use of advanced robotics, and the application of advanced analytics of big data in supply chain management: place sensors in everything, create networks everywhere, automate anything, and analyze everything to significantly improve performance and customer satisfaction.”

Rather than trying to manually consolidate all of these different applications and systems, a digital supply chain platform integrates these diverse technologies. A cloud-based collaborative platform makes it easy to connect with data, wherever it is. It makes information sharing effortless, and grows as you bring in new partners, systems, and networks. Manage all of this data efficiently through a digital platform. This lets you surface the most important information and use it to drive smart business decisions, based on the latest industrial trends.

The move to an integrated, centralized platform has enormous benefits, and we’ve broken down some of the key areas.

Digitizing your supply chain processes drives benefits throughout your business. A digital supply chain platform will reduce operational overheads, streamline partner interactions, drive lasting change, and transform how you think and work.

The best cloud-based supply chain software doesn’t just focus on what’s happening now, it plans for what’s coming over the horizon.

We’re going to see even greater advances in technology, including:

A digital platform will connect to all of these leading-edge technologies, making their power easily accessible to forward-looking supply chain businesses.

The need for stronger controls is only going to increase:

We cover the entire journey of your products, from sourcing, product development, ordering, and production to quality, ESG controls, and sustainability management. Our supply chain platform digitally transforms your business— regardless of your industry.

At the same time, your business gets to bring its costs down, shorten lead times, manage risk more effectively, and meet strict regulations and compliance. Even better, the Topo cloud collaboration platform provides your business with the agility and resilience to really move the needle. Enjoy a customized, low-code approach to create the tools and reports you need.

Contact us today and see how we can revolutionize your business.