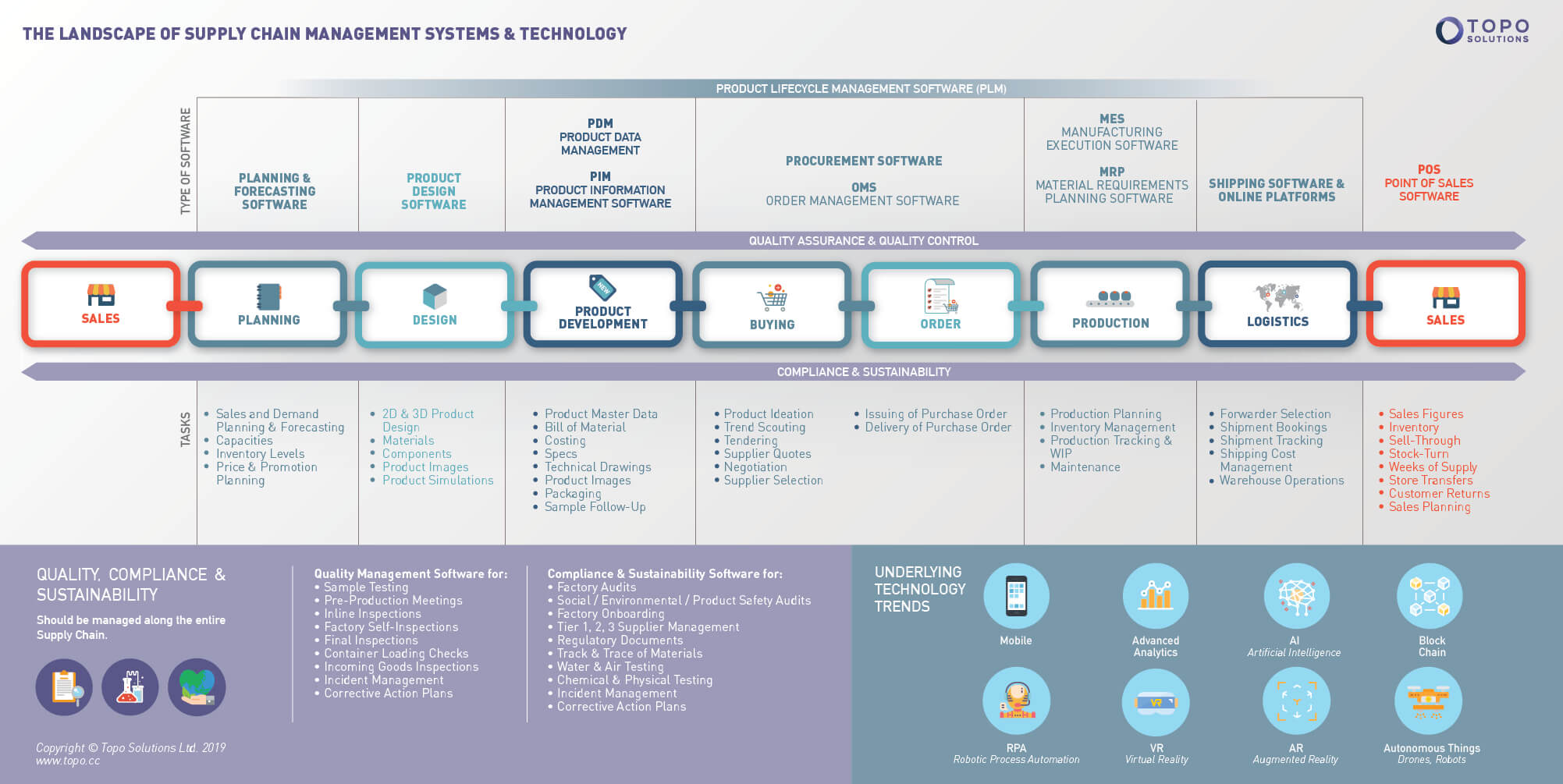

Technology in Supply Chain Management: Who Does What?

First, let’s take a look at common software in the market that assists in different processes of a supply chain and what tasks they help to fulfill:

Planning & Forecasting Software

In the planning stage, a company foresees sales and demand for its products. Looking at analytics and data helps predict the manufacturer’s production capacities and optimize inventory levels. Based on past trends, a planner can adjust prices and plan for promotions.

Product Design Software

Enable 2D and 3D product design purposes. 3D product design software can produce photorealistic visuals of a product showing materials, texture, a 360-view of the product as well as interior components.

Product Data Management (PDM) / Product Information Management Software (PIM)

Especially critical for the product development stage, PIM and PDM software manages all data related to a product. The software helps maintain assets and product information that is distributed for marketing, sales and internal purposes like technical drawings, costing and packaging information. As a centralized catalog, the system can store specifications of a single product in different languages and makes product data available across departments and regions.

Procurement and Order Management Software (OMS)

Procurement software allows organizations to automate purchasing functions such as obtaining quotes from suppliers, and handling the approval, rejection, or cancellation of an order. Similarly, an OMS handles and streamline order processes from which an order is placed to order fulfillment. The software is also a centralized database, keeping all records of existing vendors and contracts, the records provide grounds for negotiation and supplier selection in future buying activities. It can also include inventory management, arranging shipment, tracking delivery and more.

Manufacturing Execution Software (MES)

Manages and monitors the manufacturing processes of transforming raw materials into finished goods in a factory. MES collects data of the complete production lifecycle that is delivered to manufacturers, facilitating cost reduction and improving efficiencies such as better utilization of machines and allow manufacturers to know when to expect machine maintenance.

Material Requirements Planning Software (MRP)

Performs inventory control and optimization of materials used in production and products available for customers. In a production planning stage, MRP ensures the product or material availability and inventory levels can meet the demands and identify delays in lead time related to materials.

Shipping Software & Online Platform

Once a product has ended its production cycle, the finished goods are shipped to stores or directly to customers, this is when logistics planning comes into the picture. From forwarder selection and shipment bookings to tracking and cost management, shipping software offers a one-stop solution for businesses to more secure, trackable and efficient delivery.

Point of Sales Software (POS)

Processes sales-related payments and transactions at a retail store. Many will merge this with inventory management systems that allow retailers to monitor stock levels. As all transactions are processed and stored on the system, the software goes beyond just the sales level, POS can also provide sales figures and sell-through rate and handle customer returns and stock transfer between stores.